Deck screws are specialized fasteners designed to resist corrosion, drive easily, and lay flat against the deck surface. They’re used primarily in the construction of outdoor decks and patios. These screws are made from a variety of materials, including stainless steel, copper, and brass, each with its unique characteristics and benefits.

Most of the desks are constructed using wooden planks. These planks must be fitted into the fixture of the deck by using screws. It is preferable to employ deck screws instead of using traditional wood screws.

The question must be ticking in your mind what are deck screws, and what technicalities make them differ from wood screws?

Characteristics of Deck Screws

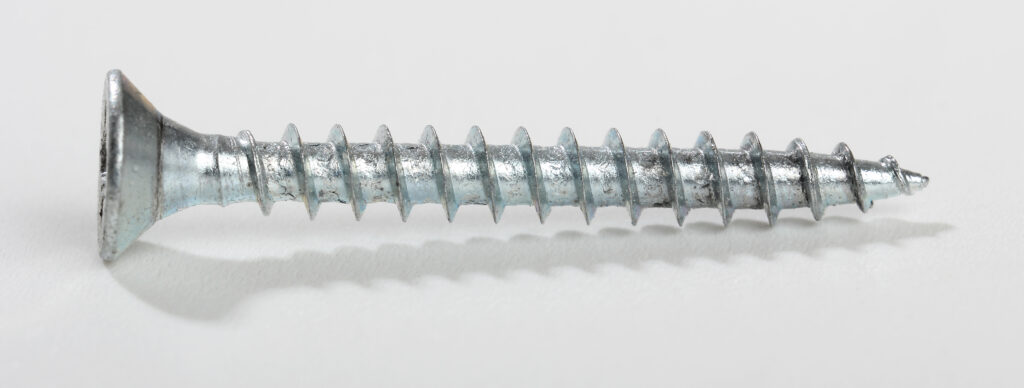

Deck screws are characterized by their sharp points and threads that extend up to the head. The sharp point and aggressive thread angle make for easy penetration into deck boards, while the flat head allows for a smooth finish. They typically have a bugle head that ensures the screws sit flush or slightly below the surface, reducing the risk of snags or tripping hazards.

In addition to their distinctive physical features, deck screws are also coated or treated to resist the elements. Many deck screws are coated with a ceramic material that provides superior resistance to rust, corrosion, and fading.

This is a vital feature, given that these screws are typically exposed to outdoor conditions, including rain, snow, and even saltwater in coastal areas.

Another characteristic of deck screws is their square or star drive. Unlike traditional Phillips head screws, these types of drives reduce the risk of stripping and provide a better grip during installation.

The length of deck screws varies, but common sizes range from 1-1/4 inch to 3-1/2 inches. The size used depends on the thickness of your deck material and whether you’re securing framing members or attaching deck boards.

In summary, when selecting deck screws, it’s essential to consider their material, coating, drive type, and size to ensure a secure, lasting, and aesthetically pleasing deck construction.

Uses and Benefits

Deck screws are specifically designed for outdoor use. Their construction and material choices make them highly resistant to the elements, including rust and corrosion caused by rain and humidity. As such, they are ideal for creating long-lasting, safe, and visually appealing decks and outdoor spaces.

Their unique design features also facilitate ease of use. For instance, many deck screws have a star or square drive head that helps prevent stripping, making them easier to drive in than traditional screws.

Furthermore, the coarse, wide threads are excellent at gripping into the wood and pulling down the decking material, ensuring a secure and stable result.

Wood Screws

Wood screws are available in contrasting layouts. Their different designs categorized into two types one fully threaded shank, and the other is partially threaded shank.

One thing to consider about wood screws is that they are available le in a broad variety of different styles. Wood screws are used for building jigs, joining cabinetry and furniture, creating pocket hole joints, mounting hardware, and much more.

Modern star and square drive heads are becoming increasingly popular. On the other hand, conventional wood screws generally have semi-threaded shanks and Phillips drive tapered heads.

What are the Differences Between Wood Screws and Deck Screws?

Wood Screws vs Deck Screws

Design Differences:

Screw Heads

The main characteristics of deck screws are normally their head styles bugle-shaped heads or flat tapered are styled out for the screws to operate all the flush into your material.

You will consider the small obtrude screw heads to spike your toes as you walk on it at the very last.

Contrastingly standard wood screws according to their intended use can have a spectrum of different head types or styles.

The wood screws feature trim heads, bugle heads round heads, washer heads, and more.

Drive Type

Deck screws interestingly feature either a square (Roberts) drive or a star (TORX) drive, while considerating drive types.

So the purpose of designing both of them is to create a strong bond between the screw and the driver bit that allows them to achieve a high extent of torque and immensely reduces the odds of driver slippage and cam out.

These drive types will execute skilfully for decks and other outdoor construction but they can be slightly expensive.

By having a non-slippery or non-fail nature they’re a happy and satisfactory vibe to work with.

Featuring a Phillips drive traditional wood screws are prone to cam out, specifically operating the screw into the wood towards the end.

Although there are countless higher-level substitutes in the market, this type of wood screw is unfortunately still one the most popular types in the US.

Behaving as a good choice for most wood-crafting implementations, Roberts head wood screws with pocket hole screws are popular.

Star or TORX drive screws are considered amazingly excellent screws in the wood industry, despite the fact they tend to be more expensive than other screw kinds.

Shanks

So describing the shank, the shank is the non-threaded portion of a screw between the head and the threads.

Beneath the head, every screw usually offers a segment of unthreaded shank regardless it is a wood screw or a deck screw.

For a tight hold to occur some wood screws are fully threaded known as without shank.

To serve numerous purposes unthreaded shanks are featured in the screws. The first and foremost purpose is to drag the screw’s head into the wood because it can draw a stronger bond than fully-threaded screws can.

The other main key purpose of the non-threaded shank segment is that it is good at calming the heat build-up by the friction of the screw threads driving into wood and other materials.

Threads

For fulfilling the purpose of fast driving and less wood-splitting deck screws tend to feature huge belligerent threads.

Some of the wood screws may have aggressively large threads but most of them feature small threads.

Traditional wood screws are designed according to their usage. They are differently moduled as per their usage such as use in softwoods (pine, cedar, plywood, and MDF) feature coarse threads.

On the other hand, wood screws that are formulated for hardwoods (oak, maple, ash, etc.) feature fine threads.

Material

Deck screws have set the standard to meet that is supremely high resistant behavior to corrosion and rust so for that purpose they consume heavy-duty material known as durable in the wood industry such as polymer or epoxy-coated steel and 305 or 316-grade corrosion-resistant stainless steel.

Alloy or stainless steel is used to formulate and design standard wood screws.

They are also engineered by some kind of coating or plating depending on their intended use case. Often the use of wood screws indoors allows it to be made up of zinc-plated alloy steel.

Comparison Conclusion:

By having a comparison session between deck screws and wood screws, you would know the prior has more threading layers than the modern one.

Although the extrinsic thread layer of deck screws is thicker than wood screws. The depth of threading makes the deck screw able to cultivate into the wooden planks of the deck, allowing it to behave more powerfully.

Which fastener should I use, a deck screw or a wood screw?

For most woodcraft or carpentry projects, wood screws are a good match, by discarding their usage outdoors where they would meet harsh circumstances, this surrounding may behave to be a hazard to the life of wood screws.

As for joining chunks of wood together and producing a wooden item wood screws are ideal.

So indoor wood problems can be fixed by sticking the wood screws but for outdoor you must have to consider mister deck screws.

Deck screws are very good at decking to stick wood planks.

They are perfect to construct framing and install rails. They can stand solid in tough weather conditions and tackle a heavier weight than traditional wood screws as the wood screws are ideal for any wooden project that required to be more vigorous.

So by signing the answer to this query, Weather you chose to pick wood or deck screws, Ensure to select the right screws for your task by contemplating the key factors such as the length of the screws, the type of head (crosshead or flat), head shape (oval, round or flat).

Contemplate When Plumping for Deck Screws:

While buying deck screws, you should consider many things first comes first the drive type.

The head recess determined the drive type. Secondly, the material should be analyzed although they are normally made up of corrosion-resistant materials.

But additionally considerating corrosion resistance, you must have to check the substance states to ensure that deck screws are made up of material that should be strong and durable.

Also, while picking up the deck screws must test the length, they should be appropriately long enough to perfectly stick in the wooden planks.

But consider the word appropriate they shouldn’t be so long that they stick out of the wooden planks.

Related Topics:

How to Install Deck Screws

When installing deck screws it’s important to use the correct size, length, and head style to ensure a secure connection. It’s also important to pre-drill pilot holes in order to prevent the splitting of the wood fibers when driving the screw into place.

Start by determining which size, length, and head style are best for your project before purchasing screws.

Mark the spot on the wood where you will be installing the screw.

Using a drill bit, pre-drill pilot holes in each location that you marked for screws. For optimal performance, use a drill bit that is slightly smaller than the diameter of the shank of the screw.

Insert the screw into the pre-drilled hole.

Using a power drill, drive the screw in until it is flush with the surface of the wood.

FAQs

Q: What is the best size screw for decking?

The size of screws you use for your project will depend on the type of wood and the thickness of the material being used. Generally speaking, 3-inch or 4-inch screws are suitable for most applications.

Q: Should I use self-tapping deck screws?

Generally, self-tapping deck screws are not recommended because they can cause the splitting of the wood fibers. Instead, it is best to drill pilot holes prior to installation. This helps ensure a secure connection and prevents the splitting of the wood fibers.

Q: How often should I replace my deck screws?

Regularly inspect your screws for signs of wear and tear such as cracks or corrosion. The frequency with which you need to replace them will depend on the climate and environment in which they are used but should be replaced at least every couple of years.

4 thoughts on “What Are Deck Screws? Ultimate Guide”